Description

Product Overview

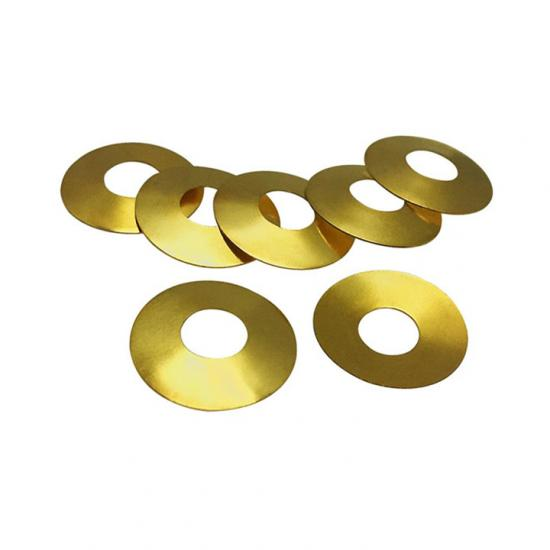

This precision-engineered coin cell spring is custom-designed for CR2032 coin cell cans, featuring strict dimensional specifications: outer diameter of 15.4 mm × height of (1.2±0.03) mm × thickness of 0.2 mm, with a lightweight profile of merely 0.1 ounces per unit. It exhibits ultra-high dimensional precision and robust elastic recovery performance, ensuring seamless integration into internal battery assemblies and sustained operational stability under cyclic pressure conditions.

Material & Craftsmanship Advantages

Dual-Performance Gold-Plated Coating

Fabricated from high-grade stainless steel with a uniform gold-plated finish, the spring offers two core functional advantages:

- Superior Corrosion Resistance: Forms a dense protective barrier against electrochemical oxidation and chemical degradation, rendering it suitable for long-term service in humid or corrosive operating environments.

- Stable Electrical Conductivity: Minimizes contact resistance between battery electrodes and external circuits, ensuring uninterrupted current transmission to meet the operational demands of high-reliability electronic devices.

Precision Machining & Surface Quality

The spring surface undergoes precision polishing to achieve a smooth, impurity-free finish, complying with the stringent cleanliness and tolerance requirements for precision battery internal assembly. This eliminates the risk of short circuits or component damage caused by surface defects.

Compatibility & Supporting System

Broad Model Compatibility

While optimized for CR2032 coin cell cans, we also provide a full suite of matching components for mainstream coin cell models including CR2016, CR2025, and CR2450, covering diverse application scenarios.

One-Stop Procurement Solution

We offer a comprehensive product portfolio, including multi-material coin cell cans (304 stainless steel/316 stainless steel/aluminum-coated), multi-specification stainless steel/pure aluminum gaskets, and wave springs. This enables customers to realize integrated procurement of all battery assembly components.

Core Functional Highlights

- Precise Elastic Contact: Delivers consistent and uniform preload to ensure tight contact between battery electrodes and circuits, preventing contact failure induced by vibration, thermal expansion, or contraction.

- Buffering & Pressure Mitigation: Absorbs mechanical stress generated during battery charge-discharge cycles, protecting internal components from structural damage and extending battery service life.

- Stable Current Conduction: The gold-plated surface maintains low contact resistance even after prolonged use, meeting the high-reliability requirements of mid-to-high-end electronic devices.

Application Scenarios

As a key elastic component for coin cells, this product is ideally suited for devices with strict requirements for corrosion resistance, electrical conductivity, and assembly precision:

- Smart wearable devices: Smart watches, fitness trackers, wireless earbuds

- Industrial equipment: High-precision sensors, remote monitoring terminals, automated control modules

- Medical instruments: Portable diagnostic devices, wearable health monitors, low-power medical equipment

- Production & R&D fields: Battery assembly lines, equipment maintenance, scientific research testing platforms

Quality Compliance

All stainless steel raw materials comply with ASTM A240 international standards, ensuring excellent mechanical properties and elastic stability. The gold-plating process adheres to ASTM B456 specifications, guaranteeing uniform coating thickness and adhesion strength. The product’s dimensional accuracy conforms to ISO 286 tolerance standards, fully satisfying the assembly requirements of precision electronic components.