Description

Atomfair Electrolytic Nickel Foil – International Product Specification

Product Overview

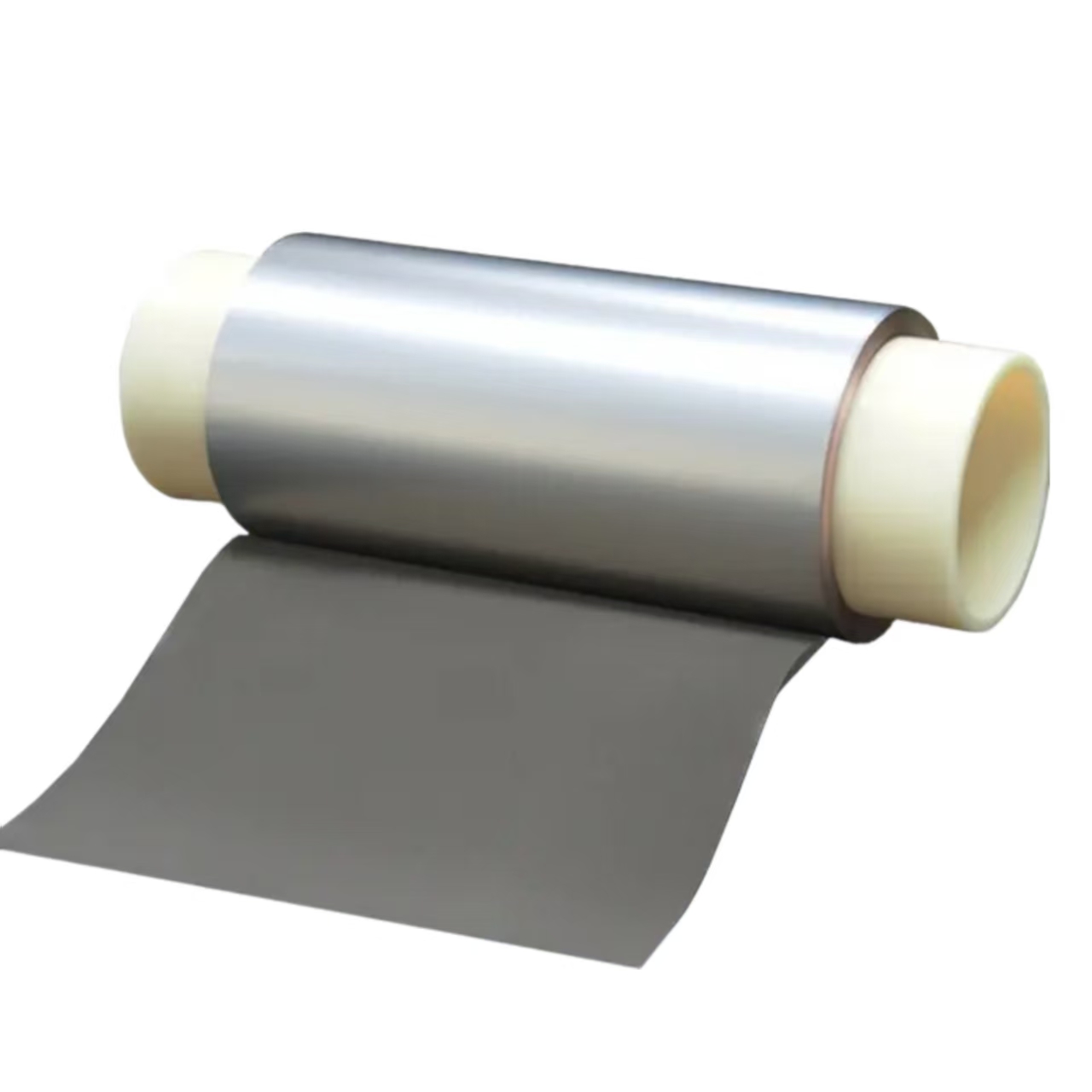

Atomfair Electrolytic Nickel Foil is precision manufactured through advanced electrolytic processing using Grade 1 electrolytic nickel as the raw material. The product features a smooth, clean surface with excellent flatness, superior ductility, low impurity content, and high purity (nickel content ≥99%).

Its high purity delivers exceptional corrosion resistance and electromagnetic shielding performance. Compared with rolled nickel foil, it offers significantly wider width, greatly improving material utilization rate in post-processing. Customizable surface roughening treatment (Ra 1.5um or above) is available to enhance hydrophilicity, adhesion, and adsorption, ensuring firm bonding with other materials and preventing delamination.

Product Specifications

| Parameter | Specification | Note |

|---|---|---|

| Thickness | 5-50um | Tolerance: ±5% (complies with ASTM B463-20 standard) |

| Width | ≤1330mm | Wider than conventional rolled nickel foil |

| Purity | ≥99% | Grade 1 electrolytic nickel raw material |

| Surface Treatment | Smooth (standard); Roughened (custom) | Roughened surface Ra ≥1.5um |

Product Performance

| Performance Indicator | Specification | Test Standard |

|---|---|---|

| Appearance | Silver-white, dense surface structure, high smoothness | Visual inspection per ASTM B463-20 |

| Tensile Strength (σs) | 660-1100 N/mm² | ASTM E8/E8M-21 |

| Elongation (δ) | 1.0-10% | ASTM E8/E8M-21 |

| Resistivity | 0.076 Ω·mm²/m | ASTM B193-18 |

| Average Temperature Coefficient of Resistance (α) | 0.006 /℃ | ASTM B193-18 |

| Corrosion Resistance | Stable in air, water, alkalis, and various acids | ASTM G31-20 |

Core Advantages

- Superior Mechanical Properties: Combines high hardness with excellent plasticity and toughness, adapting to diverse processing scenarios such as stamping, cutting, and bending.

- Excellent Corrosion & Thermal Performance: High electrical conductivity and heat resistance, maintaining stability in complex working conditions (e.g., high humidity, chemical environments).

- Favorable Magnetic Properties: Inherent magnetism meets specific magnetic requirements in applications like electronic components and aerospace systems.

- Low Volatility & High Stability: Low gas content and vapor pressure ensure outstanding stability and strong environmental adaptability during long-term use.

- High Material Utilization: Wider width (up to 1330mm) compared to rolled nickel foil reduces material waste and improves post-processing efficiency.

- Customizable Surface: Optional roughening treatment enhances adhesion with other materials, suitable for bonding and composite applications.

Application Fields

1. Battery Industry

Core components including battery connection plates, tabs, current collectors, and separator plates, widely used in lithium-ion batteries, nickel-metal hydride batteries, and fuel cells.

2. Consumer Electronics

Key materials for electric bicycles, laptops, smartphones, electric vehicles, MP3/MP4 players, iPads/iphones, digital cameras, and camcorders, used in circuits, shielding, and connectors.

3. Industrial Equipment

Applied in instruments and meters, telecommunications equipment, vacuum devices, and special bulbs, leveraging its corrosion resistance and conductivity.

4. Other High-End Scenarios

Corrosion-resistant packaging for electronic components, electronic tags, and aerospace thermal control systems, benefiting from its high stability and environmental adaptability.

Quality Assurance & Certifications

Atomfair implements strict quality control throughout the production process of electrolytic nickel foil, covering raw material inspection (purity testing of Grade 1 electrolytic nickel), electrolysis process monitoring, and finished product testing (thickness, tensile strength, corrosion resistance, etc.).

The product complies with international standards such as ASTM B463-20 (Standard Specification for Electrolytic Nickel Foil) and RoHS 2011/65/EU. We hold ISO 9001 Quality Management System Certification to ensure consistent quality for global customers.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.