Description

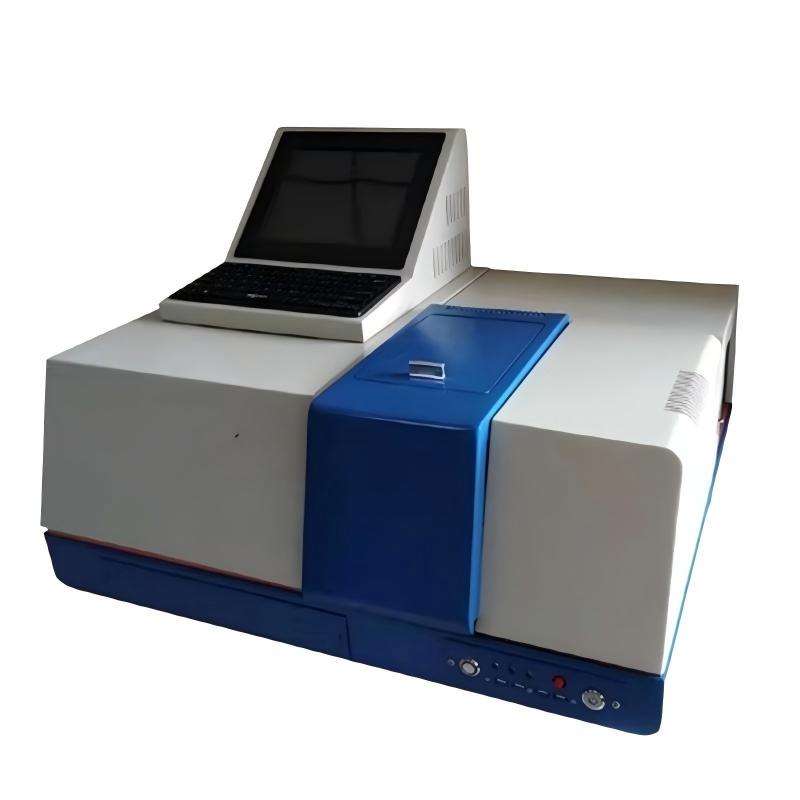

Atomfair TFD-4000 Free Silicon Dioxide Tester in Occupational Disease Prevention Dust

I. Product Application Scenarios

Applicable to the analysis and testing of various dusts in the production environment of electric power, coal and other industries, including silica dust, coal dust, boiler dust, asbestos dust, cement dust, electric welding fume, etc. Such dusts are characterized by high free silicon dioxide content and high dispersion (mostly respirable dust), which are harmful to dust-exposed personnel, and can accurately detect their free silicon dioxide content.

II. Core Detection Principle

Based on infrared spectroscopy, α-quartz has specific strong absorption bands at 12.5μm (800cm⁻¹), 12.8μm (780cm⁻¹) and 14.4μm (694cm⁻¹) in the infrared spectrum. Within a certain range, its absorbance value has a linear relationship with the mass of α-quartz, and quantitative determination is achieved by measuring absorbance.

III. Performance Indicators

| Item | Specification & Parameter |

|---|---|

| Wave number range | 2.5-25μm |

| Wave number accuracy | ≤±2 cm⁻¹ |

| Scan mode | Full wavelength scanning |

| Slit adjustment | 5 gears adjustable |

| Stray light | ≤0.5%T(4000-650cm⁻¹) |

| Sample particle size requirement | Ground to less than 8μm |

| Detection amount | α-quartz detection amount is 0.01mg |

| Relative Standard Deviation (RSD) | 0.64%-1.41% |

| Average recovery rate | 96.0%-99.8% |

| Applicable ambient temperature | 18℃-24℃ |

| Applicable ambient relative humidity | Less than 50% |

IV. Core Characteristics of the Instrument

- Excellent detection capability: Fast and sensitive, can identify three crystal forms of free silicon dioxide with high detection accuracy.

- Convenient and efficient operation: Supports batch detection, Windows full Chinese operation interface, easy to use; can quickly create and print experimental reports with efficient data processing.

- High cost performance of equipment: Less equipment investment, no complex supporting facilities, suitable for automatic analysis scenarios.

- Strong adaptability: Robust design with practical appearance size, can adapt to various analysis and testing environments; moving parts are composed of electromagnetic drive device and precision mechanical guide rail, with loose requirements for use environment.

- Advanced technical configuration: Integrates detection components, signal amplifier and 24-bit analog-to-digital converter, directly outputs digital signals to reduce electronic noise; 24-bit analog-to-digital converter improves weak signal detection capability; high-intensity light source with spherical reflection device to obtain uniform and stable infrared radiation.

- Perfect data processing function: Supports peak marking, peak area integration, baseline calibration, spectral background baseline memory and correction, spectral data accumulation operation, %T & ABS conversion; standard file format storage for convenient data sharing and processing, supports spectral file storage and printing.

V. Instruments and Reagents Required for Detection

(I) Instruments

- Porcelain crucible and crucible tongs

- Box-type resistance furnace or low-temperature ashing furnace

- Analytical balance (sensitivity 0.01mg)

- Drying oven and desiccator

- Agate mortar

- Tablet press and pellet mold

- 200-mesh dust sieve

- Infrared spectrophotometer (record the spectrogram of 900cm⁻¹~600cm⁻¹ with X-axis abscissa, calibrate zero and 100% at 900cm⁻¹, and express absorbance with Y-axis ordinate)

(II) Reagents

- Potassium bromide (GR or spectral pure): Pass through 200-mesh sieve, grind by wet method, dry at 150℃ and store in desiccator for standby

- Anhydrous ethanol (AR)

- Standard α-quartz dust (purity above 99%, particle size <5μm)

VI. Detection Process

- Sample collection: Collect samples in accordance with the determination purpose. The dust collected on the filter membrane can be directly used for determination when the amount is more than 0.1mg.

- Sample treatment: Accurately weigh the dust mass → fold the filter membrane and ash (temperature <600℃) → cool and dry → mix and grind with 250mg potassium bromide → dry at 110℃±5℃ for 10min → prepare pellets by pressurizing 25MPa; treat the blank filter membrane as control at the same time.

- Standard curve drawing: Weigh different masses of standard α-quartz dust from 0.01mg to 1.00mg, mix with 250mg potassium bromide respectively to prepare pellets → scan and determine → draw three standard curves at 800cm⁻¹, 780cm⁻¹ and 694cm⁻¹ with absorbance value as ordinate and quartz mass as abscissa, and obtain regression equation (800cm⁻¹ curve is preferred when there is no interference).

- Sample determination: Scan the sample pellet and blank control pellet respectively, record the absorbance value at 800cm⁻¹ (or 694cm⁻¹) for 3 repetitions → take the average value and deduct the absorbance of blank control → obtain the mass (m) of free silicon dioxide through the standard curve.

- Calculation: The calculation formula for free silicon dioxide (α-quartz) content in dust is: SiO₂(F)=(m/G)×100%, where m is the measured mass of free silicon dioxide (mg), G is the mass of dust sample (mg).

VII. Notes

- The quartz dust used for samples and standard curves shall be fully ground to ensure that more than 95% of the particle size is less than 5μm to avoid the particle size affecting the determination results.

- The ashing temperature of coal dust samples shall be controlled below 600℃. If it contains a large amount of kaolin components, ashing above 600℃ will cause interference.

- If the dust contains clay, mica, amphibole, feldspar and other components that cause interference near 800cm⁻¹, the standard curve of 694cm⁻¹ can be selected for quantitative analysis.

- The laboratory shall control the temperature at 18℃~24℃ and relative humidity <50% to reduce the random error of measurement.

- The analysis conditions for preparing the quartz standard curve shall be completely consistent with those of the tested samples to reduce the systematic error.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.

Reviews

There are no reviews yet.