Description

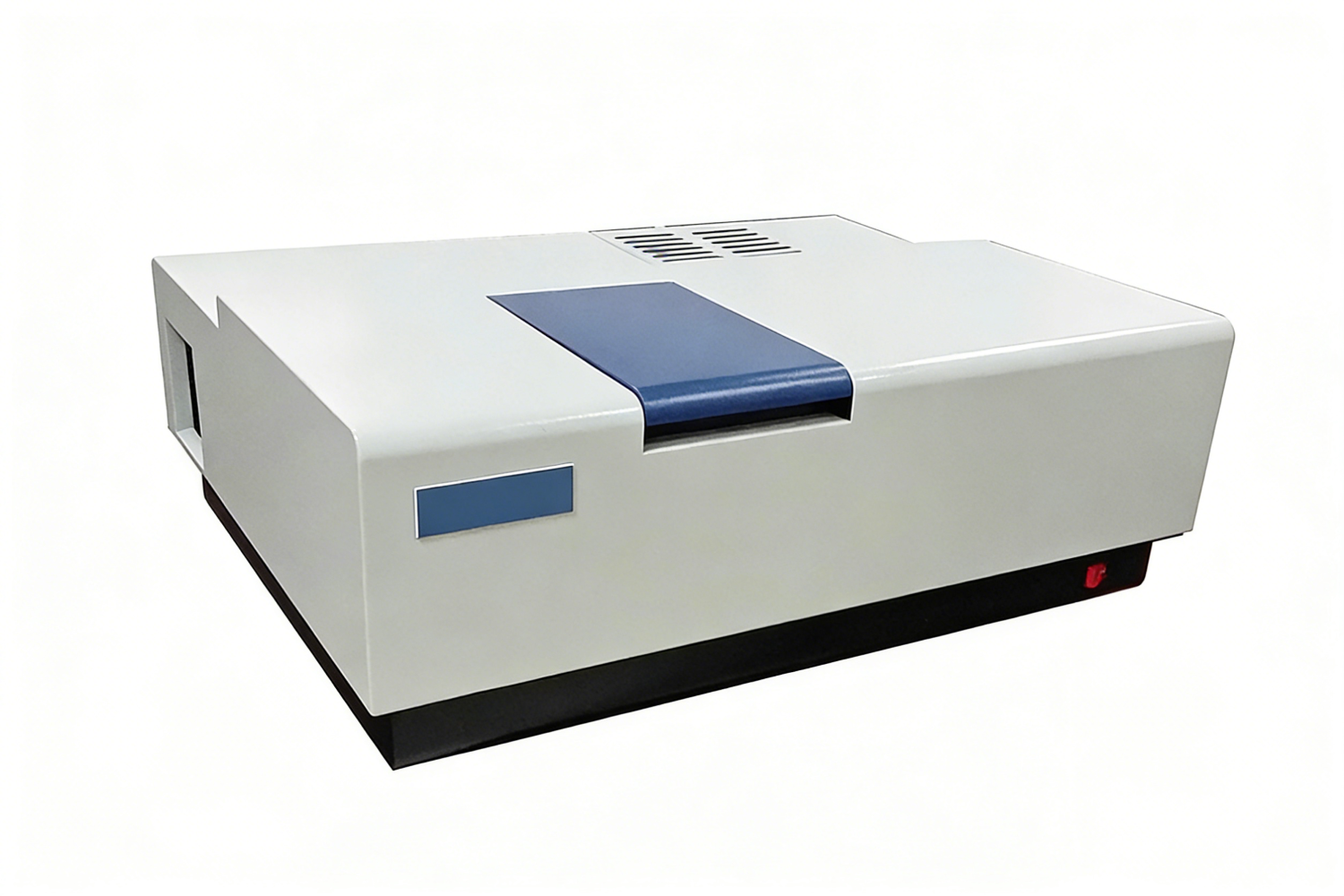

Atomfair-NIR-937 Near Infrared Spectrophotometer

1. Product Overview

Atomfair-NIR-937 Near Infrared Spectrophotometer is a high-performance professional NIR spectral analysis instrument, equipped with a brand-new imported optical system and high-sensitivity detection components, specialized in qualitative & quantitative analysis, rapid component screening, purity testing and non-destructive analysis of substances in the near-infrared band. No complex sample pretreatment is required, it can directly detect solid, powder, particle, liquid, paste and other sample forms with high efficiency and no consumable loss. All core indicators meet international standards with excellent spectral resolution, fast scanning speed and strong data stability. It meets the needs of scientific research experiments, industrial online quality inspection, rapid raw material sorting, finished product quality control and other scenarios. Widely used in food & grain, pharmaceutical & chemical, agricultural breeding, feed testing, textile raw materials, polymer materials, tobacco and other industries, it is a core laboratory equipment for rapid, non-destructive and accurate analysis.

2. Core Features

- Imported high-end optical configuration: Equipped with imported long-life & high-stability NIR special light source + high-performance Indium Gallium Arsenide (InGaAs) detector, with sensitive spectral response, accurate signal acquisition and ultra-low stray light to ensure stable and reliable detection data in the full band; standard high-precision holographic concave grating with high light splitting efficiency, effectively reducing spectral interference and improving analysis accuracy.

- Ultra-wide spectral coverage & excellent performance: Full band coverage of spectral wavelength range 900-2500nm, wavelength accuracy ±2nm, wavelength repeatability ≤1nm, spectral resolution ≤8nm, minimal baseline drift, signal-to-noise ratio ≥10000:1 (RMS). It can accurately capture weak spectral characteristics of samples to meet qualitative and quantitative analysis of trace components and impurities.

- Non-destructive & rapid testing without pretreatment: Core advantage is non-contact non-destructive testing. Solid samples are loaded directly and liquid samples are tested directly, no complex pretreatment steps such as digestion, extraction and color development are needed. Single test only takes a few seconds, greatly saving testing time and labor costs, no chemical reagent loss, green and pollution-free.

- Full compatibility with multi-form samples: Adapt to powder, particle, flake, block solid, various transparent/turbid liquid, paste, emulsion and other sample forms; equipped with special sample cell, solid sample cup, liquid cuvette and other suitable accessories, no additional modification required, one machine meets the testing needs of multiple sample types.

- High-efficiency intelligent detection system: Support multiple modes such as rapid wavelength scanning, continuous spectral acquisition, fixed-point wavelength testing, quantitative modeling analysis, fast scanning speed, real-time output of spectral maps and analysis results; built-in professional NIR spectral analysis software with spectral library retrieval, baseline correction, smoothing and denoising, multivariate calibration modeling functions, support model saving and calling, easy to master for beginners.

- High stability & low drift: Optical core components adopt constant temperature sealed moisture-proof design, effectively isolating environmental temperature, humidity, vibration and other interferences, no obvious baseline drift during long-term continuous operation, excellent data repeatability; no vulnerable and consumable parts of the whole machine, long service life of light source, simple maintenance and low failure rate, suitable for both laboratory and industrial field environments.

- Accurate quantitative & convenient qualitative analysis: Can accurately analyze the content of moisture, protein, fat, starch, sugar, fiber, ash and other components in samples with wide concentration linear range and small quantitative error; support spectral matching and retrieval of unknown samples, quickly complete raw material authenticity identification, component screening, batch consistency judgment with intuitive and reliable qualitative results.

- Humanized design & flexible expansion: High-definition LCD display interface with Chinese and English bilingual switching, concise and easy-to-understand operation menu; support USB data export, computer online control, automatic test report generation and printing; optional accessories such as optical fiber probe and automatic sampler can be selected on demand, adapt to customized needs such as online continuous detection and remote sampling analysis with strong expandability.

3. Specification Parameters

| Item | Detailed Parameters |

|---|---|

| Model No. | Atomfair-NIR-937 |

| Wavelength Range | 900~2500nm |

| Spectral Resolution | ≤8nm |

| Wavelength Accuracy | ±2nm |

| Wavelength Repeatability | ≤1nm |

| Photometric Accuracy | ±1%T |

| Photometric Repeatability | ≤0.2%T |

| Signal-to-Noise Ratio | ≥10000:1 (RMS, full band) |

| Baseline Drift | ≤0.0008Abs/h (constant temperature, 1500nm) |

| Scanning Speed | ≤2s/time (full band fast scanning) |

| Detector | Imported high-performance Indium Gallium Arsenide (InGaAs) detector |

| Light Source | Imported long-life stable halogen light source for NIR special use |

| Dispersion Element | High-precision holographic concave diffraction grating |

| Compatible Sample Forms | Solid (powder/particle/flake/block), liquid, paste, emulsion |

| Core Test Functions | Spectral scanning, qualitative analysis, quantitative modeling, component content determination, spectral retrieval, batch comparison |

| Data Output | USB interface, computer online connection, data storage, report printing, spectral map export |

| Environmental Adaptability | Temperature 5~35℃, Humidity ≤80%RH (no condensation) |

| Power Supply | AC 220V±10%, 50/60Hz, low power consumption |

| Machine Features | Constant temperature optical system, anti-seismic & anti-interference, no consumables, non-destructive testing, long life & maintenance-free |

4. Typical Applications

- Food & grain industry: Detection of moisture, protein, starch content in grain (wheat/rice/corn); screening of fatty acid composition, moisture and impurities in edible oil; quantitative analysis of protein and fat in milk powder & dairy products; rapid analysis of sugar and moisture in snack food, authenticity identification of raw materials.

- Pharmaceutical & chemical industry: Rapid determination of active ingredients in traditional Chinese medicinal materials, authenticity identification of prepared slices; purity detection of western medicine raw materials, ratio analysis of pharmaceutical excipients; quantitative analysis of chemical raw materials (alcohols, esters, polymers), rapid screening of residual organic solvents.

- Agriculture & feed field: Quality grading of grains and beans; detection of moisture, protein, crude fiber, crude fat content in feed; quality screening of seed breeding, origin traceability and component analysis of agricultural products.

- Material industry: Qualitative analysis of plastic, rubber, polymer components; purity identification of textile raw materials (cotton/flax/silk/chemical fiber); rapid detection of solid content and component ratio of coatings and adhesives, NIR spectral characteristic analysis of nanomaterials.

- Tobacco industry: Quantitative analysis of tobacco leaf moisture, total sugar, reducing sugar, nicotine content; judgment of tobacco shred batch consistency, quality grading and screening of tobacco raw materials.

- Scientific research field: NIR spectral experiment training in universities, research on spectral characteristics of new materials, rapid qualitative identification of sample components, development and verification of NIR quantitative models.

- Industrial quality inspection: Rapid acceptance of incoming raw materials, online component monitoring in production process, random inspection of finished product quality, greatly improving production line efficiency and reducing quality inspection costs.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.