Description

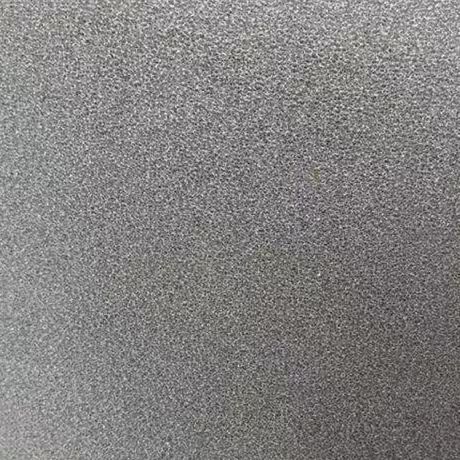

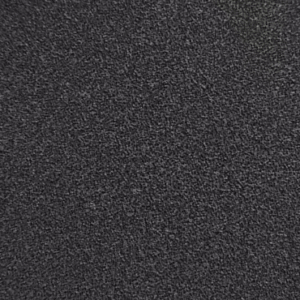

Nickel-Cobalt Foam Product Specification

1. Basic Technical Parameters

| Parameter Type | Specification Range |

|---|---|

| Product Name | Nickel-Cobalt Foam |

| Thickness | 1~2 mm |

| PPI (Pore Density) | 110~130 ppi |

| Porosity | 95~98% |

| Open Pore Rate | >98% |

| Pore Size | 0.2~0.3 mm (corresponding to 110~130 ppi) |

| Material Composition | Nickel: 10%, Cobalt: 90% |

| Areal Density | 100~2000 g/m² |

| Bulk Density | 0.1~2.0 g/cm³ |

| Dimension Specification | Customizable (see standard sizes below) |

Standard Dimension Specifications

| Length (mm) | Width (mm) | Thickness (mm) | Remarks |

|---|---|---|---|

| 10 | 10 | 0.5~2.0 | Thickness customizable |

| 20 | 20 | 0.5~2.0 | Thickness customizable |

| 50 | 50 | 0.5 | Standard specification |

| 50 | 50 | 1.0 | Standard specification |

| 50 | 50 | 1.5 | Standard specification |

| 50 | 50 | 2.0 | Standard specification |

| 100 | 100 | 0.5 | Standard specification |

| 100 | 100 | 1.0 | Standard specification |

| 100 | 100 | 1.5 | Standard specification |

| 100 | 100 | 2.0 | Standard specification |

2. Core Features

- Superior Sound Absorption: Porous structure enables acoustic diffuse reflection and micro-pore sound attenuation, delivering exceptional noise reduction performance.

- Ultra-High Specific Surface Area: Outperforms other porous materials in specific surface area under the same open pore rate.

- Efficient Electromagnetic Shielding: Provides excellent shielding effectiveness against specific electromagnetic wave ranges.

- Easy Processability: Compatible with mechanical processing such as cutting, stamping, and bending.

- Excellent Fire & High-Temperature Resistance: Maintains structural stability at temperatures above 1100℃ and exhibits non-flammable properties.

- High Thermal Conductivity: Uniform pore structure ensures rapid heat transfer when heated.

- Superior Air Permeability: Offers stable gas and fluid flow, ideal for filtration applications.

- Excellent Corrosion Resistance: Resistant to various acids and alkalis, demonstrating strong environmental adaptability.

3. Main Application Fields

- Chemical Power Sources: Electrode materials for fuel cells.

- Chemical Engineering: Catalysts and catalyst supports, filtration media, separator media (e.g., oil-water separators, automotive exhaust purifiers, air purifiers), distillation column packings, and condenser heat exchange materials.

- Electrochemical Engineering: Hydrogen production via electrolysis, electrocatalytic processes, electrochemical metallurgy, etc.

- Thermal Engineering: Damping materials and high-efficiency thermal conductive materials.

- Functional Materials: Sound insulation, vibration absorption, buffering, electromagnetic shielding, stealth technology applications, flame retardancy, and thermal insulation.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.

Reviews

There are no reviews yet.