Description

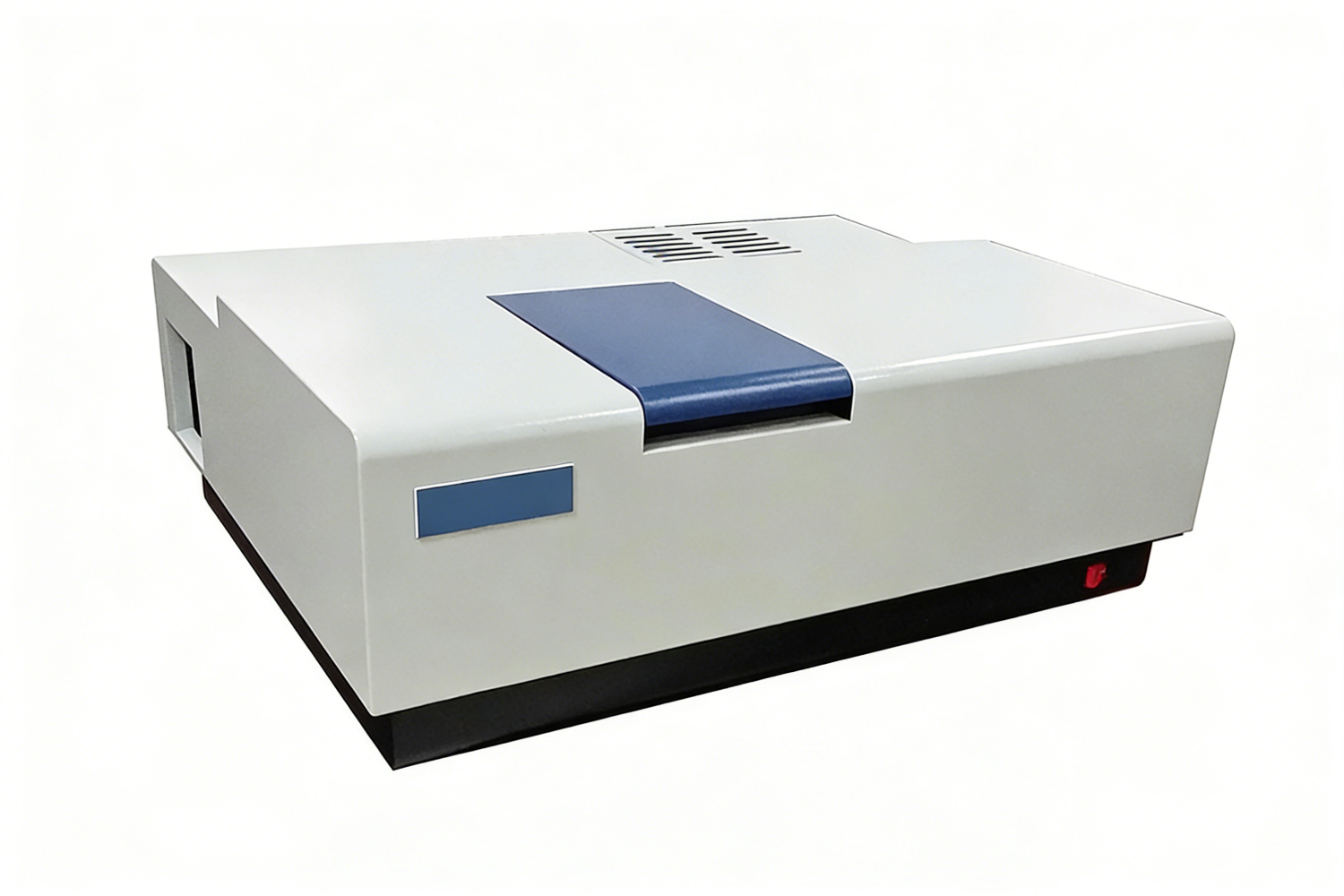

Atomfair-IR-618 Infrared Spectrophotometer (Fourier Transform Infrared, FTIR)

1. Product Overview

Atomfair-IR-618 Fourier Transform Infrared Spectrophotometer is a high-performance intelligent infrared spectral analysis instrument, built with imported high-end optical core components and precise interferometer system. All core performance indicators meet international standards, specialized in infrared qualitative identification, structural analysis, component quantification, purity testing and unknown substance analysis of materials. It enables non-destructive testing of solid, powder, liquid, film, paste and all sample forms, with excellent spectral resolution, fast scanning speed, high signal-to-noise ratio, stable spectral baseline, accurate and repeatable test data. No tedious sample pretreatment is required, it adapts to the usage needs of routine laboratories, research institutes, quality inspection institutions, industrial quality control and other scenarios. Widely used in chemical raw materials, pharmaceutical preparations, polymer materials, rubber & plastic, food testing, textile fibers, environmental testing, metallurgy & mineral products and other industries, it is a core precision testing equipment in the field of infrared spectral analysis.

2. Core Features

- Imported high-end optical configuration: Equipped with imported long-life & high-stability infrared light source, high-sensitivity Mercury Cadmium Telluride (MCT) detector, high-precision gold-plated reflector, combined with high-energy Michelson interferometer. Sufficient infrared luminous flux, wide spectral response range and ultra-low stray light, effectively capture weak infrared characteristic absorption peaks of samples to ensure accurate and reliable test results.

- Excellent core performance indicators: Full mid-infrared band coverage of spectral wavelength range 4000-400cm⁻¹, spectral resolution ≤4cm⁻¹, wavenumber accuracy ±0.01cm⁻¹, wavenumber repeatability ≤0.005cm⁻¹, signal-to-noise ratio ≥50000:1 (RMS). Fast full-band scanning speed for single test and minimal baseline drift, capable of accurately completing differential analysis of trace components, trace impurities and substances with similar structures.

- Non-destructive adaptation for all sample forms: Perfectly compatible with multiple test methods including KBr pellet method, paste method, liquid film method, coating method, diffuse reflection and transmission method; standard equipped with full set of accessories such as special KBr pellet mold, liquid sample cell, solid sample holder, film fixture, no additional modification required. All samples including solid, powder, viscous liquid, transparent/opaque film, fiber, particle can be directly tested with non-destructive and no consumable loss.

- Intelligent & efficient operating system: Built-in high-definition touch screen, equipped with professional infrared spectral analysis software, supporting Chinese and English bilingual switching with concise and easy-to-understand interface; with automatic baseline correction, spectral smoothing, peak labeling, baseline translation, difference spectrum analysis, spectral library retrieval and other functions, built-in standard infrared spectral library, capable of quickly completing qualitative matching of known substances and structural analysis of unknown substances, supporting spectral storage, comparison, export and printing.

- Accurate qualitative & practical quantitative analysis: Accurately determine chemical structure and functional group composition of substances through characteristic infrared absorption peaks, complete raw material authenticity identification, batch consistency judgment and component screening; support establishment of standard curves to realize quantitative analysis of main components and impurity content in samples with wide concentration linear range and small quantitative error, meeting the needs of routine quantitative testing.

- Stable, durable & easy maintenance: Optical core components adopt sealed moisture-proof and constant temperature anti-interference design, effectively isolating external interference such as environmental temperature and humidity, vibration, dust, no obvious drift during long-term continuous operation with excellent data repeatability; no vulnerable and consumable parts of the whole machine, long service life of light source and detector, maintenance-free calibration of interferometer, low failure rate, suitable for long-term stable use in laboratories with extremely low maintenance cost.

- Humanized detailed design: Integrated compact structure of the whole machine with exquisite volume, occupying small bench space; low noise operation, no mechanical transmission wear parts with strong anti-seismic and anti-interference performance; support USB data export, computer online control, automatic test report generation, spectral format compatible with mainstream infrared analysis software with strong data interoperability, meeting the needs of spectral output for scientific papers and filing of quality inspection reports.

- Cost-effective & flexible expansion: Basic configuration meets the needs of routine infrared qualitative and quantitative analysis, optional extended components such as Attenuated Total Reflection (ATR) accessory, diffuse reflection accessory, gas cell, high-temperature sample stage can be selected on demand, adapting to the testing needs of special samples (volatile liquid, corrosive sample, high-temperature sample), taking into account basic testing and high-end scientific research experiments with outstanding cost performance.

3. Specification Parameters

| Item | Detailed Parameters |

|---|---|

| Model No. | Atomfair-IR-618 |

| Spectral Range | 4000~400 cm⁻¹ (Full mid-infrared band) |

| Spectral Resolution | ≤4 cm⁻¹ |

| Wavenumber Accuracy | ±0.01 cm⁻¹ |

| Wavenumber Repeatability | ≤0.005 cm⁻¹ |

| Signal-to-Noise Ratio (SNR) | ≥50000:1 (RMS, full band) |

| Scanning Speed | ≤0.5s/time (Full band fast scanning) |

| Baseline Drift | ≤0.0002 Abs/h (Constant temperature condition) |

| Detector | Imported high-sensitivity Mercury Cadmium Telluride (MCT) detector |

| Light Source | Imported long-life ceramic light source for infrared special use |

| Dispersion Element | High-precision gold-plated reflector + Michelson interferometer |

| Compatible Sample Forms | Solid (powder/particle/fiber/block), liquid, film, paste, cream |

| Test Methods | Pellet method, Transmission method, Diffuse reflection method, Liquid film method, Coating method |

| Core Functions | Spectral scanning, Baseline correction, Peak labeling, Spectral library retrieval, Qualitative analysis, Quantitative modeling, Difference spectrum analysis, Data export |

| Data Output | USB interface, Computer online connection, Spectral storage, Report printing, PDF/Spectral format export |

| Environmental Adaptability | Temperature 15~30℃, Humidity ≤70%RH (No condensation) |

| Power Supply | AC 220V±10%, 50/60Hz, Low power consumption |

| Machine Features | Sealed optical system, Constant temperature anti-interference, No mechanical wear, Low noise, Calibration-free maintenance, Non-destructive testing |

4. Typical Applications

- Chemical industry: Structural qualitative analysis of organic/inorganic compounds, purity detection of chemical raw materials, screening of solvent residues, component analysis of intermediates, ratio identification of coatings/adhesives/inks.

- Pharmaceutical industry: Authenticity identification of traditional Chinese medicinal materials/slices, purity detection of western medicine raw materials, qualitative analysis of pharmaceutical excipients, component consistency analysis of capsules/tablets, confirmation of functional group structure of antibiotics.

- Material industry: Qualitative analysis of plastic/rubber/resin components, structural analysis of polymer materials, identification of fibers (cotton/flax/silk/chemical fiber), determination of film materials, infrared spectral characteristic testing of nanomaterials.

- Food industry: Qualitative screening of food additives, quality testing of edible oil, component identification of milk powder/dairy products, safety testing of food packaging materials, structural analysis of starch/sugars.

- Environmental protection: Qualitative analysis of organic pollutants in sewage, component analysis of waste gas, screening of harmful substances in solid waste, detection of organic residues in soil.

- Metallurgy & Mineral Products: Qualitative analysis of mineral components, confirmation of metal oxide structure, purity detection of metallurgical auxiliary materials, infrared characteristic analysis of rare earth materials.

- Scientific research & Teaching: Infrared spectral experiment training in universities, structural research and development of new materials, component analysis of unknown substances, establishment of infrared spectral quantitative models, theoretical verification of functional groups and chemical bonds.

- Industrial Quality Control: Incoming raw material acceptance, component monitoring in production process, random inspection of finished product quality, batch stability judgment, greatly improving quality inspection efficiency and accuracy.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.