Description

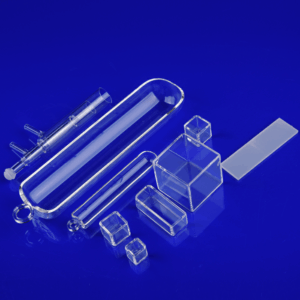

1. Product Overview

This product is high-purity boron nitride (BN) ceramic, an advanced structural ceramic material with excellent thermal stability, chemical inertness, and electrical insulation. Its performance parameters have been verified through precise characterization and standardized testing, making it suitable for international scientific research needs in fields such as materials science, semiconductor processing, and high-temperature chemical synthesis. It is a core container/substrate choice for high-end high-temperature experimental scenarios.

|

Product Type

|

Specification

|

Dimension Details (mm)

|

|

Boron Nitride Crucible

|

2ml

|

Outer 16 × Inner 12 × Height 20

|

|

Boron Nitride Crucible

|

3ml

|

Outer 20 × Inner 16 × Height 18

|

|

Boron Nitride Crucible

|

5ml

|

Outer 24 × Inner 20 × Height 22

|

|

Boron Nitride Crucible

|

10ml

|

Outer 28 × Inner 24 × Height 30

|

|

Boron Nitride Crucible

|

20ml

|

Outer 32 × Inner 26 × Height 32

|

|

Boron Nitride Crucible

|

50ml

|

Outer 47 × Inner 41 × Height 45

|

|

Boron Nitride Crucible

|

100ml

|

Outer 58 × Inner 50 × Height 58

|

|

Boron Nitride Boat (with Lid)

|

50×15×15mm

|

Length 50 × Width 15 × Height 15

|

|

Boron Nitride Boat (with Lid)

|

50×20×20mm

|

Length 50 × Width 20 × Height 20

|

|

Boron Nitride Boat (with Lid)

|

100×15×15mm

|

Length 100 × Width 15 × Height 15

|

|

Boron Nitride Boat (with Lid)

|

100×20×20mm

|

Length 100 × Width 20 × Height 20

|

|

Boron Nitride Boat (with Lid)

|

100×25×25mm

|

Length 100 × Width 25 × Height 25

|

|

Boron Nitride Boat (with Lid)

|

100×40×20mm

|

Length 100 × Width 40 × Height 20

|

|

Boron Nitride Crucible

|

Customized Shape

|

Customized on demand (dimensions to be confirmed through negotiation)

|

2. Core Performance Parameter Table

|

Performance Item

|

Unit

|

Value/Description

|

Supplementary Notes

|

|

Chemical Composition (BN Purity)

|

%

|

99

|

High-purity grade with negligible impurity content

|

|

Density

|

g/cm³

|

>2

|

Dense ceramic matrix with stable structure

|

|

Leeb Hardness (HL)

|

HL

|

300

|

Good surface wear resistance, suitable for regular experimental contact conditions

|

|

Flexural Strength

|

MPa

|

35

|

Meets the mechanical strength requirements of regular experimental scenarios

|

|

Coefficient of Thermal Expansion (CTE)

|

10⁻⁶/K

|

-1~2.5

|

Low thermal expansion property, excellent thermal dimensional stability

|

|

Thermal Conductivity (Room Temperature, 20℃)

|

W/(m·K)

|

50

|

High thermal conductivity, facilitating uniform heat distribution in high-temperature scenarios

|

|

Maximum Operating Temperature

|

–

|

–

|

Varies with atmospheric environment, details as follows:

|

|

– Air Atmosphere

|

℃

|

900

|

Avoid long-term overheating to prevent oxidative degradation

|

|

– Vacuum Atmosphere

|

℃

|

1800

|

Suitable for vacuum high-temperature sintering experiments

|

|

– Inert Atmosphere (e.g., N₂, Ar)

|

℃

|

2200

|

Meets the needs of extreme high-temperature synthesis scenarios

|

|

Volume Resistivity at Room Temperature (20℃)

|

Ω·cm

|

>10¹⁴

|

Ultra-high voltage insulation property, suitable for electrical isolation scenarios

|

3. Key Performance Advantages

- Strong Adaptability to Extreme Temperatures: Withstands high temperatures up to 2200℃ in inert atmospheres. Combined with its low thermal expansion coefficient, it can stably resist sudden temperature changes, significantly reducing the risk of material failure during experiments.

- Excellent Chemical Inertness: Exhibits good corrosion resistance to most molten metals, acidic/alkaline media, making it suitable for container use in harsh reaction systems.

- Good Synergy of Functional Properties: The combination of high thermal conductivity and ultra-high resistivity enables it to simultaneously meet the dual needs of “high-temperature thermal management” and “electrical insulation isolation” in scientific research scenarios.

4. Usage Precautions

- The operating temperature in air atmosphere must be strictly controlled below 900℃. Overheating will cause BN to oxidize and form B₂O₃, which in turn affects material performance and experimental accuracy.

- Diamond-specific tools must be used for mechanical processing to avoid surface damage or structural destruction caused by regular cutting methods.

- For long-term storage, the product should be placed in a dry and sealed environment to prevent absorption of moisture in the air, which may affect the purity control of high-temperature experiments.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.

Reviews

There are no reviews yet.