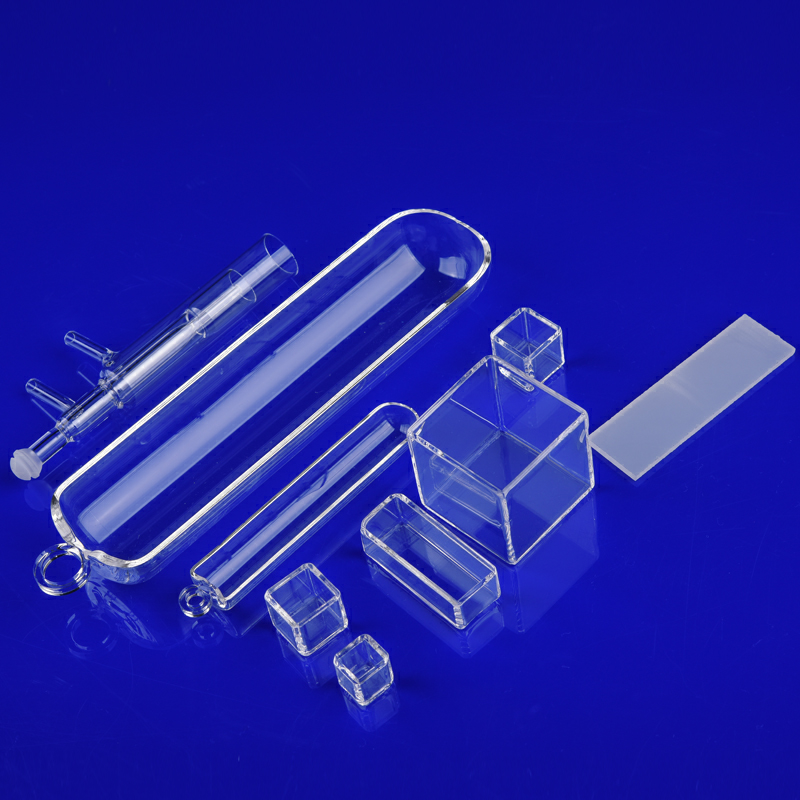

Description

Quartz Products Specification Table

| Product Name | Category | Outer Diameter (mm) | Wall Thickness (mm) | Inner Diameter (mm) | Length (mm) | Length (mm) | Width (mm) | Height (mm) | Volume | Quantity | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz Tube | Tube | 9 | 1.5 | 6 | 100 | – | – | – | – | 10 pcs | Standard Specification |

| Quartz Tube | Tube | 14 | 2 | 10 | 100 | – | – | – | – | 5 pcs | Standard Specification |

| Quartz Tube | Tube | 20 | 2 | 16 | 100 | – | – | – | – | Customizable | Standard Specification |

| Quartz Tube | Tube | 22 | 2 | 18 | 100 | – | – | – | – | Customizable | Standard Specification |

| Quartz Tube | Tube | 25 | 2 | 21 | 100 | – | – | – | – | Customizable | Standard Specification |

| Quartz Tube | Tube | 28 | 2 | 24 | 100 | – | – | – | – | Customizable | Standard Specification |

| Quartz Square Tank | Container | – | – | – | – | 20 | 20 | 20 | – | Customizable | Cubic Structure |

| Quartz Square Tank | Container | – | – | – | – | 30 | 30 | 30 | – | Customizable | Cubic Structure |

| Quartz Square Tank | Container | – | – | – | – | 40 | 40 | 40 | – | Customizable | Cubic Structure |

| Quartz Square Tank | Container | – | – | – | – | 50 | 50 | 50 | – | Customizable | Cubic Structure |

| Quartz Square Tank | Container | – | – | – | – | 60 | 60 | 60 | – | Customizable | Cubic Structure |

| Quartz Square Tank | Container | – | – | – | – | 70 | 70 | 70 | – | Customizable | Cubic Structure |

| Quartz Boat | Square Container | – | – | – | – | 50 | 20 | 10 | – | Customizable | Experimental Carrying Use |

| Quartz Boat | Square Container | – | – | – | – | 50 | 25 | 12.5 | – | Customizable | Experimental Carrying Use |

| Quartz Boat | Square Container | – | – | – | – | 50 | 30 | 15 | – | Customizable | Experimental Carrying Use |

| Quartz Boat | Square Container | – | – | – | – | 50 | 35 | 17.5 | – | Customizable | Experimental Carrying Use |

| Quartz Boat | Square Container | – | – | – | – | 50 | 40 | 20 | – | Customizable | Experimental Carrying Use |

| Quartz Boat | Square Container | – | – | – | – | 60 | 30 | 15 | – | Customizable | Experimental Carrying Use |

| Quartz Beaker | Container | – | – | – | – | – | – | – | 3000ml | Customizable | For Large-Capacity Experiments |

Atmofair Optical Quartz Glass (Research Grade)

Atmofair Optical Quartz Glass is a high-purity transparent inorganic non-metallic material for fields such as optical engineering and materials science. Its composition and performance parameters meet the strict requirements of research-grade precision experiments and device preparation, and it is suitable for scenarios such as optical systems and high-temperature environment testing.

1. Core Technical Parameters

1.1 Chemical Composition (Reference Standard: Optical Quartz Glass Standard)

SiO₂ Content: ≥99.95%

Main Impurity Element Content (Unit: ppm):

| Element | Al | Ga | Cu | Fe | Na | K |

|---|---|---|---|---|---|---|

| Content | 10-40 | <2 | <0.1 | <2 | <2 | <2 |

1.2 Mechanical Properties

| Performance Index | Standard Value |

|---|---|

| Density | 2.2g/cm³ |

| Compressive Strength | 1100MPa |

| Bending Strength | 67MPa |

| Tensile Strength | 48MPa |

| Young’s Modulus | 0.14-0.17×10⁵MPa |

| Rigidity Modulus | 7200MPa |

| Adhesion Modulus | 31000MPa |

| Mohs Hardness | 5.5-7.0 |

1.3 Thermal Properties

| Performance Index | Standard Value |

|---|---|

| Deformation Point | 1280℃ |

| Softening Point | 1780℃ |

2. Core Product Advantages

- Ultra-High Purity: SiO₂ content is over 99.95% with extremely low impurity element content, ensuring the stability of optical performance;

- Mechanical Adaptability: It has both suitable strength and hardness, meeting the processing and assembly requirements of precision devices;

- High-Temperature Stability: It has high deformation point and softening point, and can withstand extreme high-temperature experimental environments.

3. Scientific Research Application Scenarios

- Optical Device Preparation: Used as the base material for high-precision optical windows, prisms and lenses;

- High-Temperature Experimental Carrier: Suitable for high-temperature thermal testing and sample carrying components in vacuum environments;

- Material Synthesis Container: Can be used as a reaction chamber component for processes such as chemical vapor deposition (CVD) in high-purity systems.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@Atmofair.com.