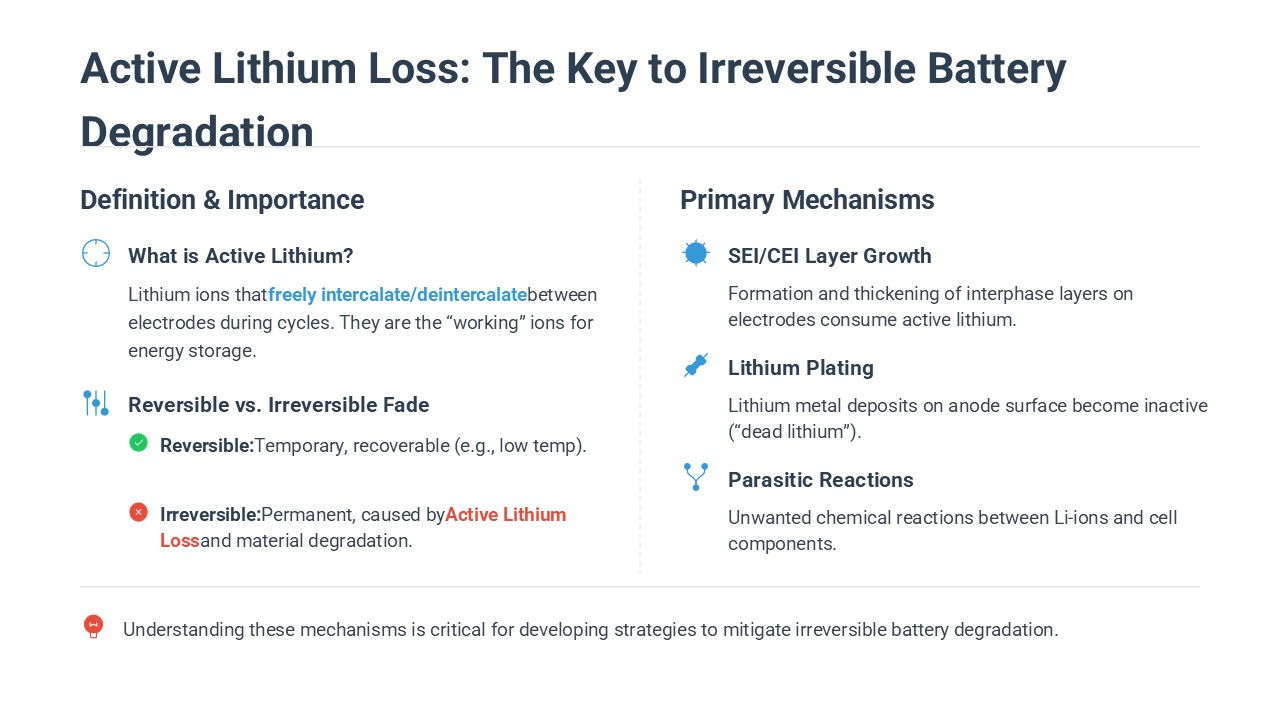

Active Lithium Loss stands as a primary culprit behind the irreversible capacity fade of lithium-ion batteries, a challenge that impacts devices from smartphones to electric vehicles worldwide. As lithium-ion batteries age, their ability to hold a charge diminishes, and distinguishing between reversible and irreversible degradation is essential for optimizing battery performance and lifespan. Reversible fade, often triggered by extreme conditions like low temperatures or high discharge rates, can be reversed when the battery returns to normal operating conditions. In contrast, irreversible fade—caused primarily by Active Lithium Loss and electrode material degradation—permanently reduces the battery’s capacity, even under optimal use.

What Is Active Lithium?

To understand Active Lithium Loss, we first need to define active lithium itself. Not all lithium ions in a battery’s electrodes participate in the charge-discharge cycle; only those that freely intercalate (insert) and deintercalate (extract) between the positive and negative electrodes qualify as active lithium—essentially the “working” lithium ions that enable energy storage and release. In a fresh battery, the amount of active lithium closely matches the charging capacity measured at a low rate, as nearly all available lithium ions are capable of participating in the cycle.

Unlike lithium ions trapped within the crystal structure of electrode materials, active lithium ions move freely between electrodes during charging and discharging. Over time, however, various mechanisms deplete this vital resource, leading to Active Lithium Loss. Common causes include the growth of solid electrolyte interphase (SEI) layers on the negative electrode and cathode electrolyte interphase (CEI) layers on the positive electrode—both of which consume active lithium as they form. Other contributors include lithium plating (where lithium metal deposits on the negative electrode instead of intercalating), parasitic reactions between lithium ions and the electrolyte, and structural degradation of electrode materials that traps once-active lithium ions.

How to Quantify Active Lithium Loss with Coin Cell Tests

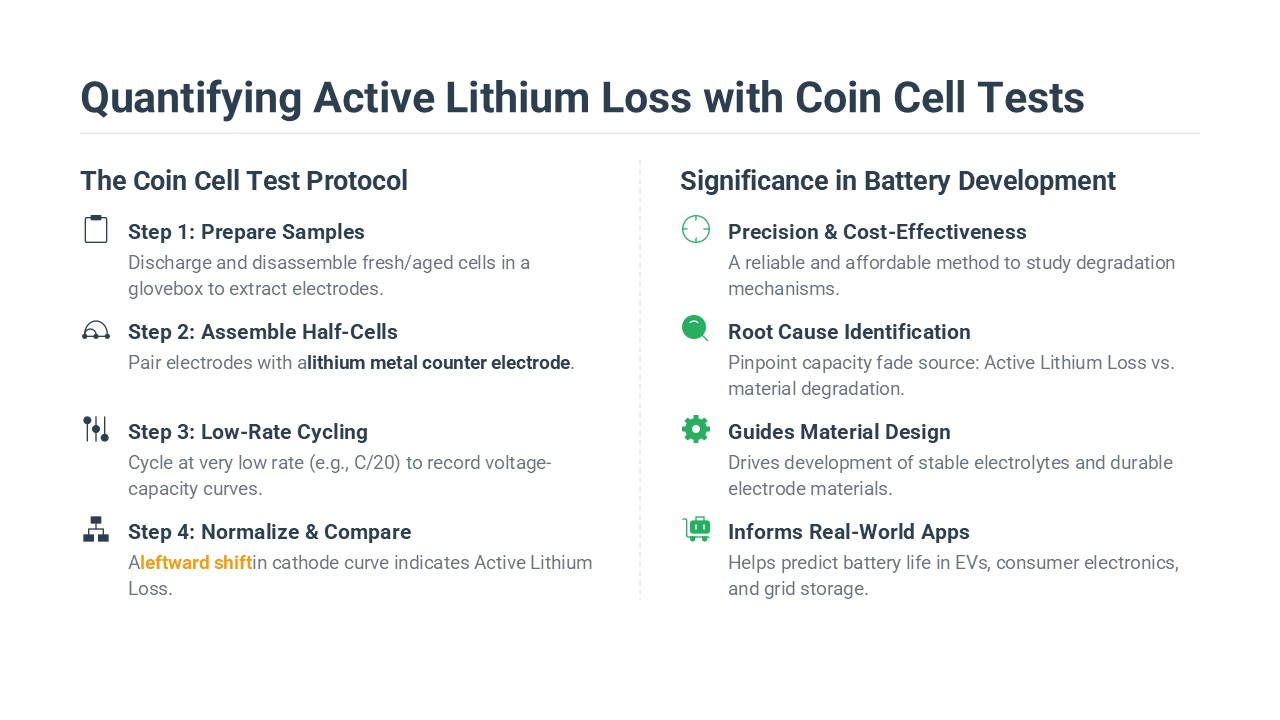

Quantifying Active Lithium Loss requires comparing the active lithium content of a fresh battery with that of an aged one, a process made possible through coin cell analysis—a widely used technique in battery research and failure analysis. Here’s a step-by-step breakdown of the method:

Step 1: Prepare Fresh and Aged Battery Samples

Start by fully discharging both a fresh (unused) battery and an aged (cycled or stored) battery to ensure all active lithium ions are in their fully intercalated state. This step eliminates residual charge that could skew measurements. Next, carefully disassemble the batteries in a controlled environment (such as an argon-filled glove box) to avoid contamination and safely extract the positive and negative electrodes.

Step 2: Assemble Coin Cell Half-Cells

For both the fresh and aged electrodes, assemble coin cell half-cells by pairing each electrode with a lithium metal counter electrode and a suitable electrolyte. Lithium metal is used as the reference because it provides a stable potential, allowing precise measurement of the electrode’s voltage during charge-discharge cycles. These half-cells—positive electrode vs. lithium (cathode half-cell) and negative electrode vs. lithium (anode half-cell)—isolate the performance of each electrode from the full battery system.

Step 3: Perform Charge-Discharge Cycles and Record Data

Run complete charge-discharge cycles on the coin cell half-cells at a low rate (typically C/20 or lower) to minimize reversible capacity effects and ensure accurate measurement of active lithium. During cycling, record the voltage vs. capacity curves for both the positive and negative electrodes. Low-rate cycling is critical here: higher rates can cause polarization or incomplete lithium intercalation, which would distort the true active lithium content.

Step 4: Normalize and Compare Curves

For the fresh battery’s half-cells, normalize the voltage curves by setting the negative electrode’s starting potential (at full discharge) to 0 V. Then, align and subtract the negative electrode’s curve from the positive electrode’s curve to reconstruct the full battery’s voltage profile. Validate this reconstructed curve by comparing it to the actual voltage curve of the fresh full battery—if the match is tight, the charging capacity of the half-cells directly corresponds to the fresh battery’s active lithium content.

Repeat this normalization and curve-reconstruction process for the aged battery’s half-cells. The key difference between the fresh and aged curves lies in the active lithium content: for the positive electrode, the aged curve will show a reduced capacity range compared to the fresh curve. This reduction—often visualized as a leftward shift of the aged positive electrode curve relative to the fresh one—represents the Active Lithium Loss. Specifically, the difference in deintercalated lithium capacity between the fresh and aged electrodes (when charged to the same cutoff potential) quantifies the amount of active lithium lost during aging.

Step 5: Separate Active Lithium Loss from Electrode Material Degradation

To ensure accuracy, it’s important to distinguish Active Lithium Loss from electrode material degradation. While Active Lithium Loss refers to the depletion of usable lithium ions, electrode material degradation involves a reduction in the electrode’s ability to host lithium ions (e.g., structural collapse or phase changes). This distinction can be made by comparing the areal capacity (mAh/cm²) of fresh and aged electrodes: a decrease in areal capacity alongside Active Lithium Loss indicates concurrent electrode material degradation.

Why Coin Cell Analysis Is Critical for Battery Development

Coin cell tests offer a precise, cost-effective way to study Active Lithium Loss, making them indispensable for battery researchers and manufacturers. By identifying the root causes of irreversible fade, engineers can design electrolytes with better SEI/CEI stability, develop electrode materials resistant to lithium plating, and optimize battery management systems to minimize Active Lithium Loss during use. For example, research published in the Journal of Power Sources (a leading resource for battery science) has used coin cell analysis to demonstrate how electrolyte additives can reduce SEI growth and extend battery lifespan by preserving active lithium.

Beyond laboratory research, coin cell data informs real-world applications. Electric vehicle manufacturers, for instance, rely on this data to predict battery lifespan and improve thermal management systems, while consumer electronics companies use it to enhance the longevity of smartphones and laptops. As the demand for high-performance, long-lasting batteries grows—driven by the shift to renewable energy and electric mobility—understanding and mitigating Active Lithium Loss will remain a top priority.