Description

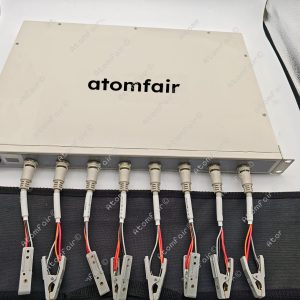

This high-precision soft package battery test fixture paired with pressure sensors is elaborately designed to meet the rigorous testing requirements of soft package batteries. This integrated testing solution combines stable clamping performance, accurate pressure measurement results and user-friendly operation experience, making it an essential tool for battery R&D, quality inspection and production testing processes.

Product Overview

This product set includes two sets of soft package test fixtures, two sets of high-precision pressure sensors, two sets of data display meters and PC control software. It can realize reliable clamping and accurate pressure monitoring during the soft package battery testing process, ensuring the accuracy and repeatability of test results.

Core Components and Technical Parameters

1. Soft Package Test Fixtures (2 Sets)

-

Fixture 1: Size 16cm × 16cm, suitable for testing small-sized soft package batteries

-

Fixture 2: Size 17cm × 22cm, suitable for testing medium and large-sized soft package batteries

-

Structural Design: 4-layer clamping plate design. This innovative structure can ensure uniform force distribution on the battery surface, avoiding battery damage caused by local pressure concentration; at the same time, the 4-layer structure can improve clamping stability and prevent battery displacement during the testing process.

2. Pressure Sensors (2 Sets)

-

Sensor 1: Measuring range 0-100kg, accuracy ±0.1% of full scale, suitable for low-pressure testing scenarios of soft package batteries

-

Sensor 2: Measuring range 0-500kg, accuracy ±0.1% of full scale, specially designed for high-pressure testing requirements, covering a variety of pressure testing scenarios

-

Core Features: The sensors have high sensitivity and fast response speed, which can capture pressure changes in real time and accurately during the testing process; all sensors are professionally calibrated before leaving the factory to ensure long-term measurement stability.

3. Data Display Meters (2 Sets)

Equipped with two independent data display meters, which are respectively matched with the two pressure sensors. The meters are equipped with high-definition digital displays, which can directly read real-time pressure values. At the same time, they support unit switching and data holding functions, facilitating on-site observation and test data recording.

4. PC Control Software

The supporting PC control software can realize remote control of the testing process. Users can freely set test parameters such as pressure range and test duration, and collect and store test data in real time. The software has an intuitive interface and simple operation, and supports data export in Excel format, facilitating subsequent data analysis and data filing.

Product Advantages

-

Complete Configuration: Integrating fixtures, sensors, display meters and control software, providing a one-stop testing solution without the need for additional accessories

-

Wide Application Range: Two sets of fixtures and sensors with different specifications can meet the testing needs of soft package batteries of different sizes and different pressure requirements

-

High Precision and Stability: The 4-layer clamping plate design combined with high-precision pressure sensors provides double guarantees for the accuracy and reliability of test results

-

User-Friendly Operation: Both the on-site display meters and the PC software adopt a simple operation design, which reduces the learning cost of operators and improves testing efficiency

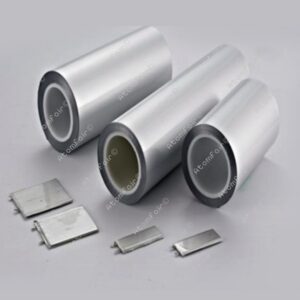

Application Scenarios

This product is widely applicable to the testing of various soft package battery products such as soft package lithium-ion batteries and polymer batteries. It can be used in scenarios such as battery compression testing, pressure cycle life testing, and performance testing under different pressure conditions in battery manufacturers, scientific research institutions and quality inspection departments.

Reviews

There are no reviews yet.