Description

Atomfair Infrared Tablet Press Mold Product Information

1. Core Product Information

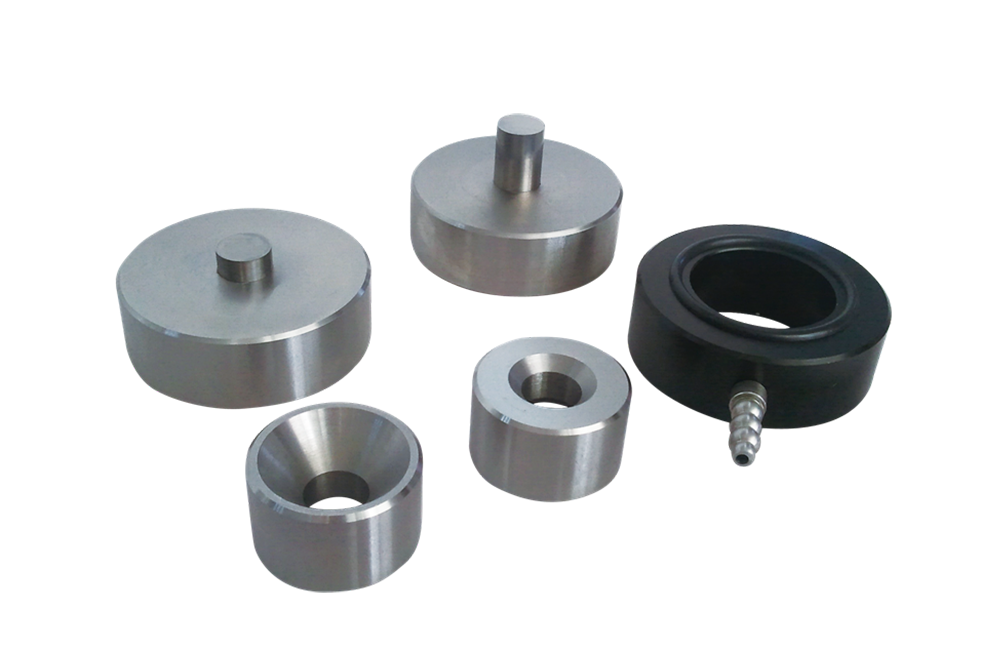

- Product Name: Infrared Tablet Press Mold

- Product Category: Infrared Sampling Accessories, Pellet Mold Series

- Product Code: Atomfair-ITPM-5179

2. Key Specifications (Compliant with International Standards)

| Item | International Standard Specification |

|---|---|

| Core Feature | Non-release Design, stable sample retention during pressing without additional demoulding operation |

| Mold Material | 304 Stainless Steel, compliant with international laboratory grade stainless steel standards, corrosion and wear resistant |

| Indenter Material | Cemented Carbide YT15, internationally universal high hardness cemented carbide material |

| Indenter Hardness | HRC85-HRC90 (Rockwell Hardness Scale, international standard, ensure indenter durability) |

| Tablet Forming Size | Φ13mm, international universal dimension standard for infrared sample preparation |

| Cavity Depth | 10mm, suitable for conventional powder sample dosage, ensure uniform tablet thickness |

| Overall Dimension | Φ58×62mm, compact structure, save laboratory bench space |

| Mold Weight | 0.77kg, easy to install and operate, suitable for various laboratory tablet presses |

| Standard Configuration | 2 Round Tablet Racks Included (Tablet inserts are sold separately) |

3. Product Application

Specially designed for sample preparation of laboratory infrared spectroscopy testing, it is the core equipment of infrared sampling process, which can press KBr powder and solid analysis samples into Φ13mm standard tablets. Compatible with the pre-sampling requirements of mainstream infrared spectrometers worldwide, it is widely used in chemical analysis, materials science, pharmaceutical research and development, environmental testing and other fields, ensuring the regularity of tablet forming and the accuracy of infrared test data, and helping to complete sample pretreatment efficiently.

4. Core Features

- Compliant & Durable Material: The mold body is made of 304 stainless steel, and the indenter is made of cemented carbide YT15 (HRC85-HRC90 high hardness), all complying with international material specifications for laboratory equipment, wear and corrosion resistant, not easy to deform, with long service life.

- Stable Non-release Design: Exclusive non-release structure avoids sample damage or contamination during demoulding, ensures tablet integrity, especially suitable for fragile powder samples, reduces sample loss and improves experimental efficiency.

- Strong International Standard Compatibility: Φ13mm forming size is the universal standard for infrared sample preparation, compatible with mainstream infrared spectrometers and tablet presses worldwide, strictly controlled dimensional tolerance ensures uniform tablet specifications and consistent test results.

- Practical & Convenient Configuration: Comes standard with 2 round tablet racks to meet the orderly storage needs of samples after pressing; the overall design conforms to the operating habits of international laboratory equipment, easy to install and clean with low maintenance cost.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.