Description

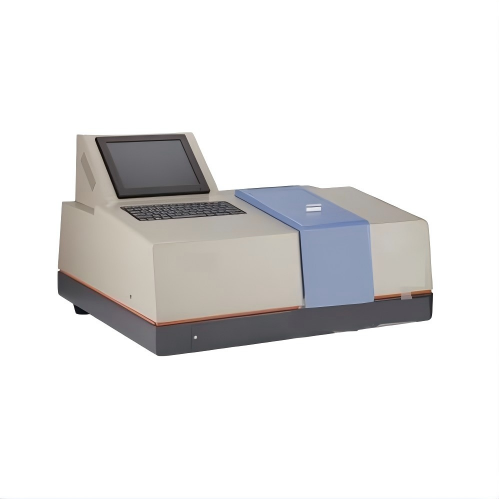

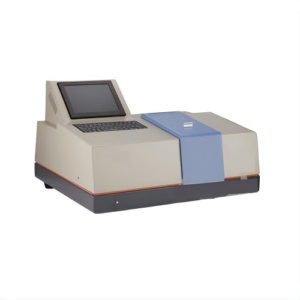

Atomfair Free Silica Tester for Disease Control & Coal Mine

Product Overview

Atomfair Free Silica Tester for Disease Control & Coal Mine is a professional testing equipment developed in accordance with international general standards, designed based on the principle of infrared spectrophotometry. Tailored for disease control centers, occupational health testing, mines, coal mines, power plants, boiler factories and other industries, it focuses on the analysis of free silica content in respirable dust in production environments. Equipped with a high-end built-in computer, no additional configuration is required, featuring fast detection speed, short cycle, high accuracy and easy operation, which can meet the needs of batch testing.

Core Functions

- Precise Quantitative Detection: Can quickly identify three crystal forms of free silica, realizing quantitative analysis by measuring the absorbance of specific absorption bands with reliable data.

- Batch Efficient Analysis: Supports batch sample testing, combined with full Chinese operation interface and intelligent data processing functions to greatly improve detection efficiency.

- Comprehensive Data Processing: Includes peak marking, baseline calibration, spectral data accumulation calculation, %T & ABS conversion and other functions, enabling quick creation and printing of experimental reports.

- Stable Data Transmission: Equipped with USB2.0 interface, spectral files can be stored and printed for convenient data sharing and filing.

Technical Parameters (International Standard)

| Item</ | Specification</ |

|---|---|

| Wavelength Range | 2.5-25μm (Wave Number Range: 4000-400cm⁻¹) |

| Wave Number Accuracy | ≤±2cm⁻¹ in 2000-400cm⁻¹ range; ≤±4cm⁻¹ in 4000-2000cm⁻¹ range |

| Scan & Slit | Full wavelength scanning, five adjustable gears of slit program |

| Stray Light | ≤0.5%T in 4000-650cm⁻¹ range; ≤1%T in 650-400cm⁻¹ range |

| Transmittance Accuracy | ≤±0.2%T (Excluding noise level) |

| Sample Requirement | Particle size less than 8μm after grinding |

| System Configuration | Built-in high-end computer, equipped with Windows XP operating system, Chinese operation platform |

| Data Interface | USB2.0 |

Product Features

- Excellent Detection Performance: High sensitivity and outstanding signal-to-noise ratio, 24-bit analog-to-digital converter outputs digital signals directly, reducing electronic noise and improving weak signal detection capability by an order of magnitude.

- Easy to Operate: No additional computer configuration required, full Chinese operation interface is intuitive and easy to understand, no complex professional training required to get started.

- Strong Environmental Adaptability: Rugged design with practical appearance size, moving parts consist of electromagnetic drive device and precision mechanical guide rail, reducing requirements for the use environment.

- Stable & Reliable Operation: High-intensity light source with spherical reflection device obtains uniform and stable infrared radiation, ensuring continuous and efficient detection process.

- Cost-Effective: Low equipment investment cost, suitable for automatic analysis scenarios, balancing practicality and cost-effectiveness.

Supporting Accessories

Powder tablet press, tablet mold, agate mortar, infrared oven (or electric drying oven), potassium bromide powder, explosion-proof dust sampler, one-hundred-thousandth electronic balance (0.01mg), high-temperature electric furnace, α-SiO₂ standard (purity above 99%)

International Universal Detection Principle (Infrared Spectrophotometry)

α-quartz exhibits strong specific absorption bands in the infrared spectrum at 12.5μm (800cm⁻¹), 12.8μm (780cm⁻¹) and 14.4μm (694cm⁻¹). Within a certain range, the absorbance value has a linear relationship with the mass of α-quartz, and quantitative determination can be achieved by measuring the absorbance.

Key Detection Notes

- Detection Capability: α-quartz detection limit as low as 0.01mg, relative standard deviation (RSD) of 0.64%~1.41%, average recovery rate of 96.0%~99.8%.

- Sample Preparation: Samples and standard quartz dust need to be fully ground to ensure that particles smaller than 5μm account for more than 95% to ensure detection accuracy.

- Environmental Control: The laboratory temperature is recommended to be controlled at 18℃~24℃ with relative humidity less than 50% to reduce random measurement errors.

- Interference Avoidance: The ashing temperature of coal dust samples should be less than 600℃ to avoid decomposition interference of kaolin components; if the dust contains clay, mica and other components, the 694cm⁻¹ standard curve can be used for quantitative analysis.

If you’re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.

Reviews

There are no reviews yet.