Description

Atomfair Customized Diamond Cut-off Wheels

To better serve your needs, we invite you to discuss your specific requirements with our team. Please contact us directly for a tailored quote.

Atomfair offers a comprehensive range of diamond cut-off wheels with diverse diameters and thicknesses, designed to be compatible with most standard abrasive cutting machines. Selecting the right cut-off wheel is critical to achieving burn-free, distortion-free cuts?saving you time and reducing consumable waste while ensuring specimens are in optimal condition for subsequent metallographic preparation steps. As diamond is the hardest material globally, our cut-off wheels excel at cutting super hard materials across industrial and laboratory applications.

Key Selection Factors for Diamond Cut-off Wheels

Choosing the appropriate wheel requires considering four core factors to match your material and cutting requirements:

- Diamond Concentration (Low/High): Directly impacts cutting load. Low concentration wheels are ideal for hard, brittle materials (e.g., ceramics, minerals) that require higher effective loads; high concentration wheels suit ductile materials (e.g., metals, plastics) needing more cutting points.

- Diamond Bond Type: Metal-bonded wheels for brittle materials (ceramics, minerals); resin-bonded wheels for ductile materials (sintered carbides, hard-phase composites).

- Diamond Particle Size (Fine/Medium): Fine grit for precise, smooth cuts; medium grit for efficient cutting of thicker or denser materials.

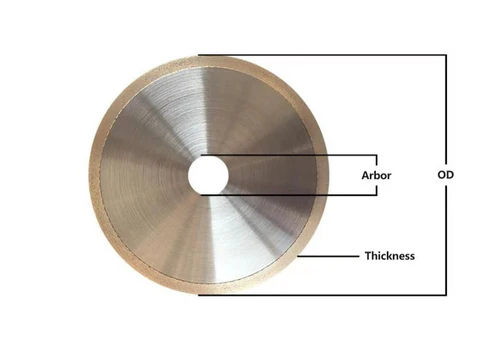

- Wheel Dimensions: Diameter, thickness, and arbor size (all customizable to your equipment and application).

Available Standard Specifications

Our diamond cut-off wheels are available in the following standard dimensions, with full customization options for arbor size and thickness (within the specified ranges) to meet your unique needs:

| Outer Diameter (OD, mm) | Thickness Range (mm) | Arbor Size |

|---|---|---|

| 60 | 0.2 – 2.0 | Customized |

| 76 | 0.2 – 2.0 | Customized |

| 80 | 0.2 – 2.0 | Customized |

| 100 | 0.2 – 2.0 | Customized |

| 110 | 0.3 – 2.0 | Customized |

| 125 | 0.3 – 2.0 | Customized |

| 140 | 0.3 – 2.0 | Customized |

| 150 | 0.3 – 2.0 | Customized |

| 160 | 0.3 – 2.0 | Customized |

| 180 | 0.8 – 2.0 | Customized |

| 200 | 0.8 – 2.0 | Customized |

| 250 | 1.2 – 2.0 | Customized |

| 300 | 1.4 – 2.0 | Customized |

| 350 | 2.2 – 3.0 | Customized |

| 400 | 2.2 – 3.0 | Customized |

Application

Ideal for cutting super hard materials in metallographic sample preparation, research laboratories, quality control departments, and industrial manufacturing. Suitable for brittle materials (ceramics, minerals) and ductile materials (metals, sintered carbides, composites) across aerospace, automotive, electronics, and materials science industries.

Purchase Information

Atomfair?s customized diamond cut-off wheels are engineered for precision, durability, and compatibility with standard abrasive cutting machines. Whether you need standard dimensions or tailored specifications, our team will work with you to select the optimal wheel for your application. Contact us today for a personalized quote and expert guidance.

If you?re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.