Description

Atomfair Diamond Grinding Papers – PSA-Adhesive Backed for Precision Grinding & Polishing

Product Overview

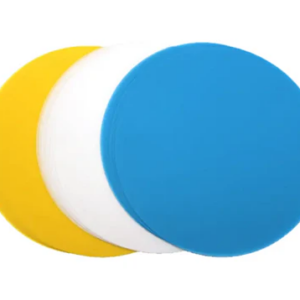

Atomfair PSA-Adhesive Backed Diamond Grinding Papers are high-performance abrasive solutions designed for consistent, uniform surface finishing across diverse hard materials. Featuring precisely graded diamond particles bonded to a durable polyester backing with a reliable pressure-sensitive adhesive (PSA), these papers ensure secure attachment to polishing equipment and deliver exceptional grinding/polishing results.

Available in sheets, discs, and rolls, they seamlessly adapt to all types of polishing machines?ideal for fiber optic connectors, rollers, hard disks, metal components, and precision engineering parts. Trusted by global industries including electronics, optics, automotive, and manufacturing, they meet rigorous international quality and performance standards.

Key Features

- Premium Diamond Coating: FEPA-compliant graded diamond particles ensure consistent material removal and ultra-smooth finishes.

- Strong PSA Backing: Pressure-sensitive adhesive provides secure, residue-free attachment to polishing equipment, reducing slippage during use.

- Durable Substrate: High-strength polyester backing resists tearing and withstands high-pressure grinding for long-lasting performance.

- Versatile Formats: Offered in discs (multiple diameters), sheets, and rolls to fit rotary, belt, and flatbed polishing machines.

- Wide Material Compatibility: Optimized for polishing metals, ceramics, semiconductors, optical components, and other hard materials.

- Global Compliance: Meets ISO 6344 abrasive standards and RoHS/REACH environmental requirements for international use.

Technical Specifications

| Abrasive Coating Material | Grit Size (FEPA Standard) | Particle Size | Disc Diameter Options (D) |

|---|---|---|---|

| Diamond (D) | #180 | 80?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #240 | 60?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #360 | 45?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #400 | 40?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #600 | 30?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #1000 | 16?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #1200 | 15?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #2000 | 9?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #2500 | 6?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #4000 | 3?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #6000 | 2?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #8000 | 1?m | 32mm, 200mm, 250mm, 300mm |

| Diamond (D) | #10000 | 0.5?m | 32mm, 200mm, 250mm, 300mm |

Additional Specifications

- Pack Size: 10 pieces per bag (industrial-grade sealed packaging)

- Backing Type: PSA (Pressure Sensitive Adhesive) – residue-free removal

- Alternative Backing: Plain-backed option available (contact for details)

- Available Formats: Discs (as above), custom-sized sheets, and rolls (custom lengths)

- Shelf Life: 24 months when stored in cool, dry conditions (relative humidity < 60%)

International Standard Compliance

- Abrasive Standards: ISO 6344:2019 (Abrasive grains?Determination of particle size distribution)

- Environmental Safety: RoHS Directive 2011/65/EU & REACH Regulation (EC) No. 1907/2006

- Quality Management: ISO 9001:2015 (Quality management systems)

Application Guidelines

- Grit Selection: Choose coarser grits (#180?#600) for initial grinding; finer grits (#1000?#10000) for precision polishing and mirror finishes.

- Surface Preparation: Ensure the polishing equipment surface is clean, dry, and flat before applying the PSA-backed paper for optimal adhesion.

- Equipment Compatibility: Discs fit standard rotary polishers; sheets/rolls are suitable for belt or flatbed polishing machines.

- Storage: Keep in sealed packaging in a cool, dry environment to protect the adhesive and abrasive coating from moisture damage.

Customization & Support

We offer tailored solutions to meet specific application needs. For assistance in selecting the right grit size, diameter, or format, contact our technical support team. Custom sizes, grit ranges, and packaging are available for bulk orders.

If you?re interested, have any questions, or have specific customization requirements, please feel free to contact us at inquiry@atomfair.com.