Description

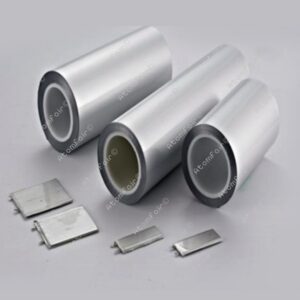

Atomfair Semi-Automatic Battery Stacker Stacking Machine for Pouch Cell Battery

Product Overview

The Semi-Automatic Battery Stacker Stacking Machine is designed to streamline the production of pouch cell batteries, enhancing efficiency and consistency in the stacking process. Utilizing a Z-shaped stacking method, this machine accurately stacks negative electrodes, separators, and positive electrodes to ensure high-quality battery assembly.

Technical Specifications

- Stacking Method: Z-shaped stacking

- Maximum Separator Roll Size: Roll separator, 3-inch core, diameter φ200mm

- Applicable Electrode Specifications: Length (20–200) mm, Width (20–200) mm, Thickness up to 18mm

- Roller Movement Stroke: 300mm

- Power Supply: AC220V/50Hz

- Power Consumption: 200W

- Air Pressure Source: 0.4MPa to 0.7MPa

- Machine Dimensions: L650mm x W400mm x H700mm

- Control Box Dimensions: L200mm x W300mm x H380mm

- Weight: 30Kg

Main Features

- Desktop Design: Can be placed on a standard desktop, saving space.

- Easy Calibration and Operation: Simple and straightforward calibration, operation, and maintenance.

- Wide Range of Electrode Sizes: Supports various sizes of battery components.

- High Efficiency: Equipped with a digital display counter for real-time monitoring of production progress.

- Foot Pedal Control: Uses a foot pedal switch to control cylinder movement, making operation more convenient.

- Compact and Aesthetic Design: Small size and attractive appearance, suitable for various work environments.

How to Use

- Prepare the Separator: Install the separator and pass it through the roller to place it on the stacking platform.

- Set Stacking Quantity: Define the desired number of stacks.

- Place Negative Electrode: Position the negative electrode on the stacking platform for alignment.

- Activate the Machine: Press the foot pedal, and the separator roller will move to cover the negative electrode.

- Add Positive Electrode: Place the positive electrode on the stacking platform for alignment.

- Repeat the Process: Press the foot pedal again to cover the positive electrode with the separator. Continue this cycle until the preset stacking quantity is reached.

- Final Steps: Manually cut the separator, extract the battery cell, and apply the sealing tape to complete the process.

Maintenance and Precautions

- After each use, clean the machine and molds to prevent residue buildup.

- Regularly check the cutting components for wear and ensure all screws and fasteners are tight.

Kindly note: Certain devices require custom manufacturing. Please consult support@atomfair.com to confirm availability before placing your order

Reviews

There are no reviews yet.